Hip Replacements Implants

Hip Replacement Implants

Dr. Kurtz describes the different types of hip replacement implants:

Cemented vs. press fit

Bearing surfaces options (metal, ceramic, and polyethylene)

Modular Dual Mobility (MDM)

Hip Resurfacing

Press Fit Implants.

Almost all acetabular and femoral components are press fit (cementless). Press fit surfaces are designed to allow the bone to grow into the implant. Press fit implants are typically made out of titanium alloys. Titanium is an excellent material for implantation in bone because titanium is more flexible than most other metals like cobalt chrome. Titanium is easy to machine and apply surface coating to. Titanium can not be used as a bearing surface because it can be easily scratched which could lead to wearing of the articular surface.

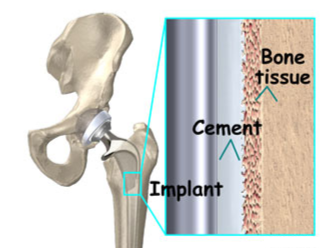

Cemented Hip Implants

Cemented femoral implants are rarely used today. Patients with fragile bones (osteoporosis or renal osteodystrophy or elderly hip fractures) may still be good candidates for a cemented femoral component. The cement works as a grout by filling in the cracks in the bone and holding the implant in the femoral canal. There is a slightly lower risk of intra-operative fracture with cemented implants, but a higher long term, failure rate as the bone remodels around the static bone cement. Cemented acetabular components had a poor track record and have not been used since the 80’s.

Bearing Surfaces

Ceramic on Poly (COP)

Ceramic on polyethylene is the most common bearing surface. The ceramic femoral head provides a hydrophobic surface that pulls lubrication into the hip joint and creates a fluid film layer between the ceramic head and the highly crossed linked polyethylene liner. This COP bearing surface wears at about 0.1mm/yr, which means it may take 60-70 years to wear through the 6-7 mm thick polyethylene liner.

Metal on Poly (MOP)

Metal on polyethylene is the second most common bearing surface. Metal head balls are made of cobalt chrome. This MOP bearing surface wears about the same as ceramic on poly, but might be just a little bit higher. A minor concern exists about possible corrosion between the metal head and the metal femoral implant.

Ceramic on Ceramic (COC)

Ceramic on ceramic is still a great bearing surface for young patients. This COC bearing surface does not show any appreciable wear. The ceramic liner can occasionally chip or crack with significant trauma which would require another surgery.

Metal on Metal (MOM)

Metal on metal bearing surfaces are rarely used in the United States these days due to the potential for metalosis and litigation. Dr. Kurtz has not implanted any MOM in the last 10 years.

Modular Dual Mobility (MDM)

MDM hip replacements allow for a larger femoral head and therefore offer more hip stability and less chance of a dislocation. With the MDM, acetabular liner is metal (instead of polyethylene) and the femoral head is polyethylene (instead of metal or ceramic). There is a second femoral head that is usually ceramic that snaps into the polyethylene femoral head. There is some concern that metalosis could occur between the metal acetabular liner and the metal acetabular implant, but we have not seen a problem there yet,

Hip Resurfacing

Hip resurfacing was popular around 2008 when some high profile athletes received hip resurfacing implants and returned to their athletic endeavors. Unfortunately, the bearing surface in hip resurfacing is metal on metal which can cause problems in some patients. Most surgeons no longer offer hip resurfacing. It may be a viable option for a very small subset of patients which are largely large athletic men.